There is no doubt that the electric car has numerous advantages, including minimal noise, an immediate response when accelerating or practically non-existent mechanical maintenance due to its engine. Obviously, there are also drawbacks, led by the limited autonomy, the complexity of recharging or the higher cost in relation to combustion vehicles.

But in this article, we are not going to break down the benefits or drawbacks of having an electric car, but rather we are going to analyze what the engine of one of them is like. We will also discuss the parts that make it up and the types of propellants that we can find on the market.

The Maintenance

In reality, the maintenance of an electric car is summed up, broadly speaking, in keeping the brake system in good condition and filling the windshield washer reservoir, little else. In addition, as there is no gearbox, clutch and many other elements, the possibility of breakdown or costly maintenance is reduced to a minimum.

Thus, the drawbacks of the electric vehicle are compensated little by little, either thanks to the progressive advance of a technology that still has a lot of room for improvement, or because governments have been intensifying their war against traditional combustion engines for years, whether this is justified or not.

How does an electric engine work

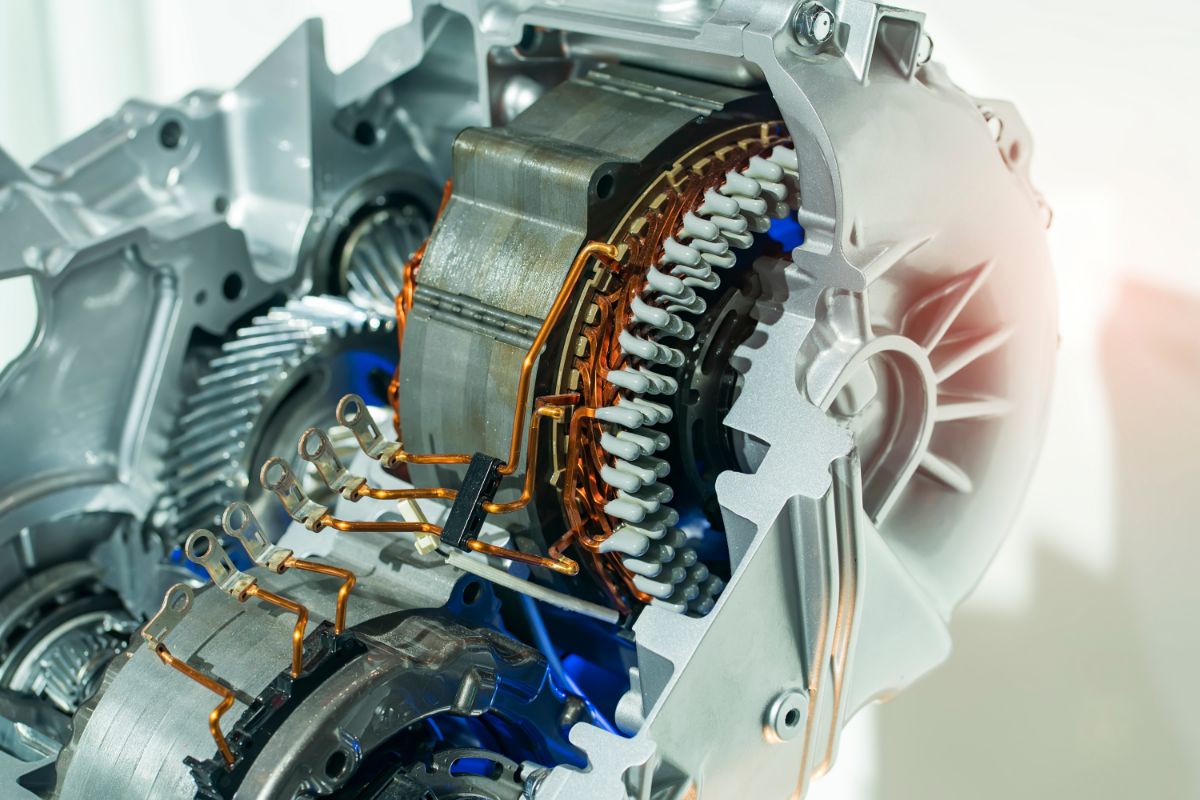

The stator of an electric motor is the fixed part of it, while the rotor is the moving part that contains a fixed magnetic field. Inside the stator, the windings are responsible for creating a rotating magnetic field created by the passage of electric current. The rotating magnetic field of the stator drags the fixed part of the rotor, making it rotate and causing some gears to make the wheels of the car move, starting the movement.

Parts of an electric motor

At first glance, we may not find many differences between a diesel or gasoline engine and an electric one when we open the hood of a vehicle, but their mechanics and operating concept differ greatly. There is no combustion, nor friction between many parts. This, from the very beginning, generates considerable smoothness of operation, as well as superior mechanical simplicity. But what parts does an electric motor consist of? Certainly not cylinders, camshafts, clutches or turbos.

How an electric motor manages energy

Depending on the phase in which the vehicle is, the engine and its components act in a certain way. Broadly speaking, we find two phases in the operation of an electric motor:

Acceleration phase: the electrical energy passes from the battery to the converter, which is responsible for transforming the direct current into alternating current. Afterward, this reaches the motor, which moves the rotor and the wheels.

Retention phase: The driver does not accelerate or brake, at which point the wheels transmit movement to the electric motor, which generates resistance and converts the kinetic energy into alternating current. When it reaches the converter, it transforms it into DC and it is stored in the battery.

How does an electric engine work?

Modern electric motors are characterized by:

- Offers a much quieter driving experience.

- Minimizing environmental pollution.

Its maintenance is very cheap in the long term and the components that an electrical system needs have a longer life expectancy. For example, no oil changes are necessary, since electric motors do not have to be lubricated. A vehicle can include one or more motors depending on the degree of electrification.

The electric motor of a car is responsible for:

- Converting the energy obtained by means of the battery into mechanical energy (generating function).

- Boosting the displacement of the car (propulsive function).

This is achieved by operating under the principles of electromagnetism: when a current is present in a magnetic field, the result is the application of a force. The force produced generates torque (or rotation), and this effect makes the motor work properly.

What parts are needed?

Now, for an electric motor to work properly, there are parts that ensure that the necessary energy will be constantly supplied so that the rotation does not stop. Some important pieces are:

- On-board charger. It receives the energy that the car gets when it is charged using an outlet.

- Bidirectional DC/AC inverter. Passes lower voltage DC power to higher voltage power to run the motor.

- Transmission. Regulates the number of vehicle gears.

- Drums. It stores the energy needed for the car to move.

- Engine control unit. It is essential for regulating the speed, direction and torque of the motor.

The traction engine

The electric motor converts the electrical energy stored in the high-voltage battery into mechanical rotational energy. In the case of LG, the technology used is permanent magnets. It is a synchronous, alternating current motor, in which the magnetic field of the rotor is created using permanent magnets made of neodymium or other rare earth.

This type of motor, the most widely used in industry, is very compact and simple but has the drawback that it requires very expensive materials to manufacture, such as the aforementioned rare earth. LG offers motors with a rated power output between 80 and 145 kW (107-195 hp) and an efficiency of 96%.

Conclusion

The popularity of electric vehicles is growing at an unstoppable rate. Thanks to the simplicity of their power train, they require little maintenance compared to a vehicle with an internal combustion engine. Thus, they not only guarantee a more sustainable future but also lower operating costs. However, some of the essential components of electric vehicles also require occasional revisions.