There are many different kinds of rotors for cars, but like every vehicle component, you will want to be very careful about the kind that you choose.

And, with every vehicle repair or maintenance, the cost is always going to be a factor. For any component, you are always going to want the best, and rotors are no exception.

Still, the value of a good product is also very important, and usually the prevailing factor in any car decision.

Brake rotors come in several different kinds of materials, and there are four main types of brake rotors in the rotor family. Learn more about the different types of rotors for cars here.

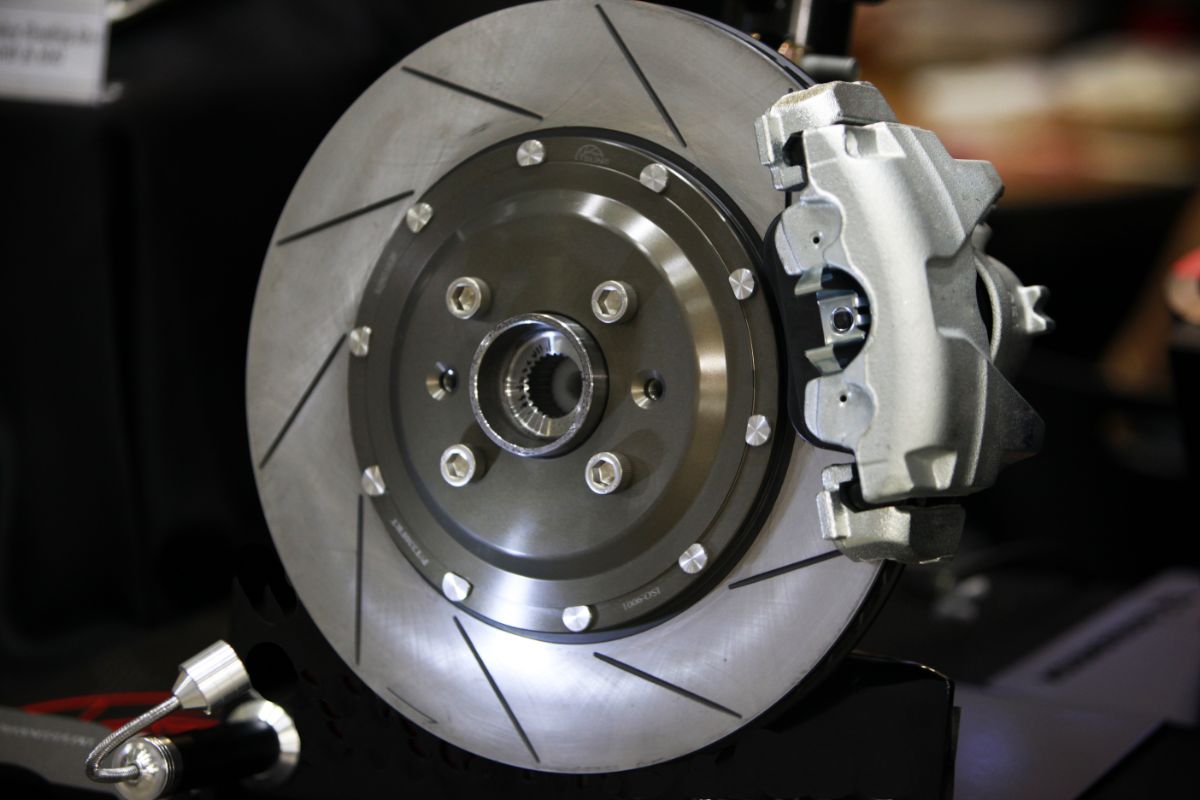

The Function of Brake Rotors

It is impossible to determine how to pick a brake rotor if you don’t understand what they do. The primary purpose of a brake rotor is to help to stop your car.

Brake rotors or discs should be checked as often as you get your brake pads checked. Brake rotors are as important in the brake system of the vehicle.

They are the discs that the brake pads press down on when the vehicle’s wheels are spinning. When they press down, the brake pads stop the tires and the car comes to a stop.

These components need to be designed in a way that lasts, as they will have several tonnes of steel clamping down on them several times in one trip alone.

You can’t have hot rubber meeting hot steel under a combustion engine without a disaster without a few parts in between to buffer the kinetic and thermal (heat and movement) combination happening here. The components of the brake system also include the brake calipers.

These components work together to convert movement into heat so that the wheels come to a stop. The rotors are the part that disperses the heat.

Without the right rotor, the brakes are going to deteriorate faster, and this is a disaster for anyone on the road around this car. You want the right kind of rotor with the right kind of brake pad to work together to prevent this disaster.

Materials Used in Brake Rotors

When you are looking at brake rotors, the material they are made of is going to be high on your list of things that matter to you. There are six common materials used in brake rotors. They are:

- Cast iron

- Steel

- Layered steel

- Aluminum

- High carbon

- Ceramic

1. Cast Iron

Cast iron is the most old-fashioned kind of brake rotor. It is also among the heaviest, and most reliable. You’ll also find it the most expensive for both of those reasons.

It is still among the most popular choices for brake rotors today because it is a material you just can’t beat when it comes to weight and effectiveness for the task at hand.

A cast-iron brake rotor is often two pieces, and will make your car heavier, but gets the job done.

2. Steel

Steel is a material that has been a favored vehicle component material for a long time. A steel brake rotor is preferred by many over cast iron as it will weigh less, and can work with heat a lot better than cast iron.

When you think of using cast iron pots on the stove and stainless steel ones, you might like the stainless steel ones better for practical purposes, as nice as it is to cook with cast iron once in a while.

Steel brake rotors are just the same, they just perform a different role. They do something with heat to get the job done.

These rotors won’t have the durability that cast iron rotors will have, and will cause noise when they warp over time. This is an easy repair though.

Layered steel is another kind of rotor material where steel is layered in sheets and then laminated in order to create the brake rotor. This kind of material for brake rotors makes layered steel rotors more resistant to warping than traditional steel rotors.

Cars that brake on and off are going to have their rotors replaced regularly, and layered steel rotors are ideal for this kind of vehicle. However, layered steel works well on any car’s rotor.

3. Aluminum

Aluminum is a very common vehicle material for parts because it responds to heat well and it resists heat well. Brake rotors need to be made of something that dissipate heat in a matter of milliseconds.

Aluminum is good for that and is also a common material for the rims or wheels for the tires.

4. High Carbon

High carbon brake rotors are rotors that have been made with iron, but also have carbon elements in their structure.

This is a brake rotor that can withstand heat and disperse it or dissipate it in a very efficient manner when a vehicle is going several miles an hour.

The carbon content helps to prevent the rotor from warping or cracking and also helps to eliminate the noise of the brakes. These are not the most affordable brake rotors however.

5. Ceramic

Ceramic brake rotors are another common material, and ceramic is being found in more vehicle components today than it ever has been. This is another material that disperses heat quickly, and also has a very high capacity to withstand heat.

With so many other choices in material, you just have to go with your instinct when it comes time to choose the best brake rotor for you. But ceramic is going to be a fail-safe.

Types of Brake Rotors

There are a few different kinds of main brake rotors. They include:

- Blank and smooth

- Drilled

- Slotted

- Drilled and slotted

1. Blank and Smooth Brake Rotors

Blank and smooth are the most common kind of brake rotors for the newest cars. They are also the largest and allow the brake pads to create the kind of friction needed to stop the car.

These are durable brake rotors as well. There are basic and premium levels of blank and smooth rotors, and either is good for the average driver.

For drivers that like to speed or perform in their cars, this is not the rotor for you. The material in blank and smooth basic rotors is steel and will have a thicker internal component that impacts the rotors cooling mechanisms.

You can get blank and smooth rotors in ceramic as well but will want to spend the extra money here.

Another thing to keep in mind with these rotors is that they will create more wear and tear on your brake pads than any other kind of rotor. That is because they produce more heat.

Still, this is the most common brake rotor for a reason. Most drivers can handle these well, regardless of what material they are made of. Original equipment manufacturer (OEM) rotors will have a longer life span than any other blank and smooth rotor.

2. Drilled Brake Rotors

Drilled brake rotors are easy to identify by the many holes they have drilled across their surface. The holes appear in spiral patterns to assist with the dispersal of heat.

These holes also ensure that the surface of the rotor allow for the release of water and dust particles on its surface. These rotors are ideal in seasonal climates due to their water resistance. They won’t last as long as other kinds will though.

3. Slotted Brake Rotors

Slotted rotors have slots on the outside of the rotor’s surface where holes are in the drilled rotors. You will see these on heavier-duty vehicles such as SUVs and large trucks.

That is because these vehicles weigh more and need a heavier power to them when they come to a complete stop. Drivers that carry heavy loads frequently will also prefer slotted rotors.

The function of the slots is to create air between the brake pads and the surface of the rotor. With this air circulation, the rotors themselves can cool down faster and heat dissipates much easier. They don’t have the lifespan that other rotor types do though.

4. Drilled and Slotted Brake Rotors

This kind of brake rotor is a combination of both drilled rotors and slotted rotors. Here you have the dual advantage of heat dissipation and debris repellant. The holes and slots are also in spirals on the surface of the rotor.

This kind of rotor is ideal for the high-performance drivers, such as those with sports cars or race cars. A high-performance vehicle needs a cooling system that enables heat dissipation.

Spectators of these kinds of drivers will jest that these drivers have money to burn, literally, so they can afford the more expensive brake rotors that you will see in any drilled and slotted brake rotor lineup.

The Cost of Brake Rotors

For most drivers, replacing brake rotors is always going to come down to costs. Every good driver will try to get the best part for the lowest price, and brake rotors are no exception. Research pays off here.

Shop around and get quotes on brake rotors, but also ask what the rotors are made of from the parts suppliers that your mechanics or distributors are using.

A good brake rotor job should run you in the area of $400 to $500. This will all depend on the type of brake rotor you use, and what it is made of. This is not a job you can do on your own unless you are a mechanic, which will also come with the cost of labor.

When you are choosing brake rotors, consider what the materials will do when you have them on your vehicle. You want to ask your mechanic about noise, wear, and performance.

A premium rotor that isn’t made of the best material for what your car needs may cost you more down the road than a basic rotor. Heat dispersal is the main problem with rotor choices.

The wrong rotor for your car will wear your brake pads down, which could be an accident or best case scenario, another repair cost sooner than you want.

The reason premium rotors are premium is often due to what they are made of. This will have the largest effect on how long the rotor will last.

You might find basic rotors made from scrap metal, and a premium rotor system may not cost you that much more.

If you have to replace basic rotors made from low-quality material in a few years, you aren’t saving any money and will kick yourself later. Choose rotors and mechanics. That choose rotors that are made from the best material.

When you take your time to research what brake rotors are and what they do, the material they are made of, and how they are made will just make sense to you. You’ll want to spend the time doing that homework.

Your mechanic might not, but you’re the one driving away on them at the end of the day. Do your homework now and your brake rotor replacement will be seamless and more painless than it would be if you didn’t.